1. Function

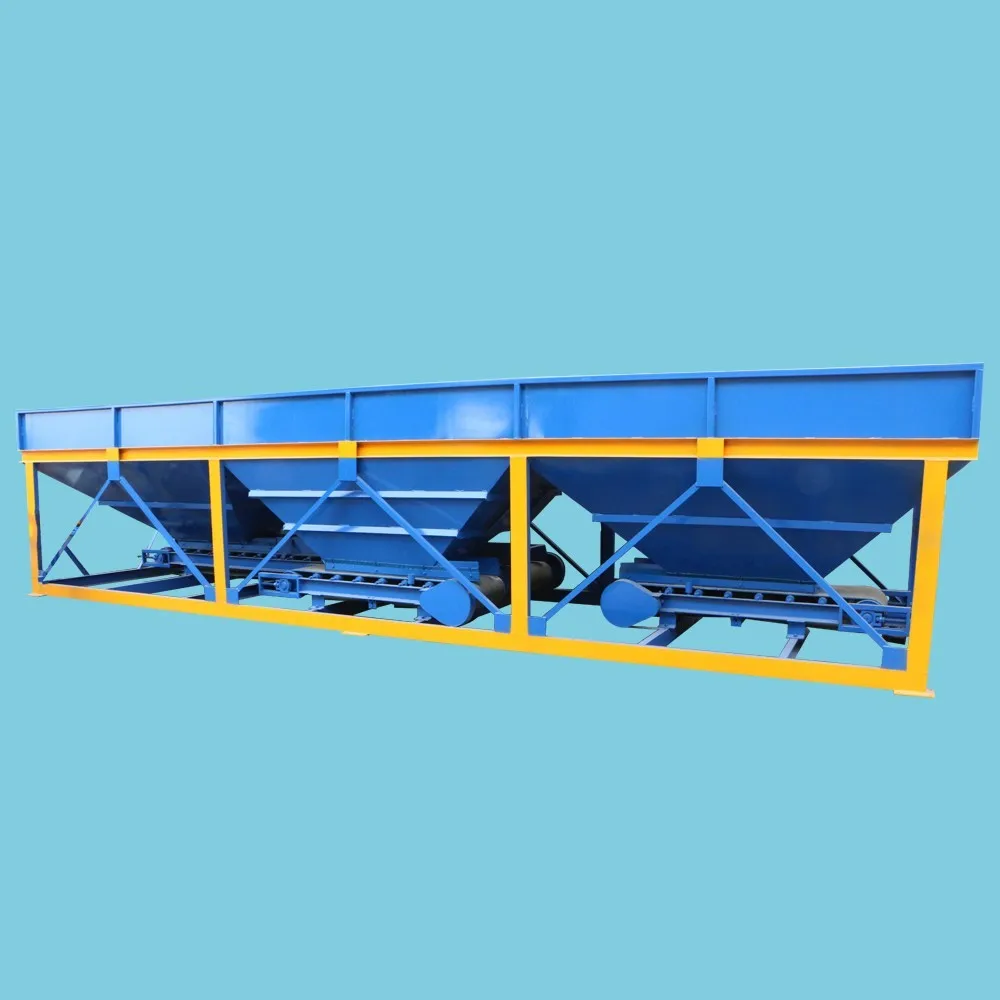

Egg laying cement concrete hollow block making machine can produce different hollow blocks,solid blocks and kerbstone by changing moulds.

2. Advanced technology

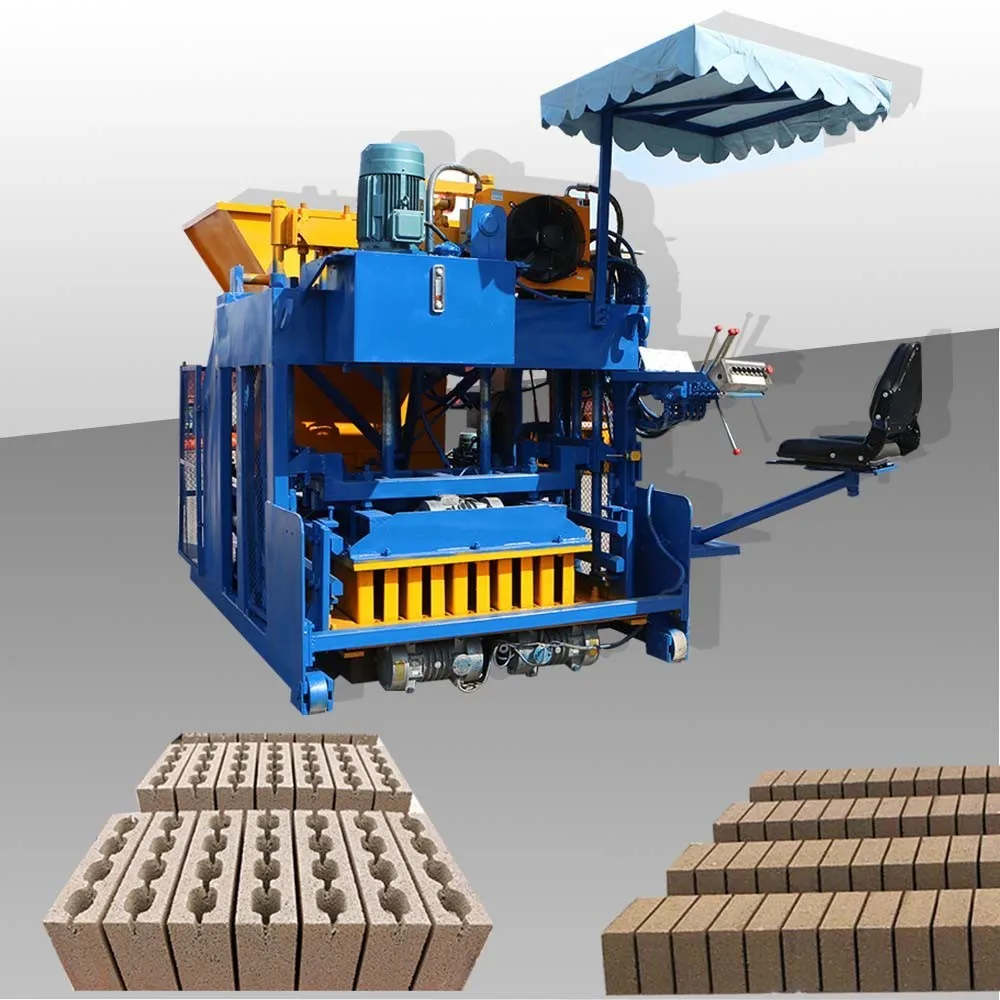

This machine adopt hydraulic molding technology, so it can produce stronger, smooth and high quality blocks. And electric walking technology adopted to this machine, so the machine can easily and simply move to convenient place.

3. High quality mould

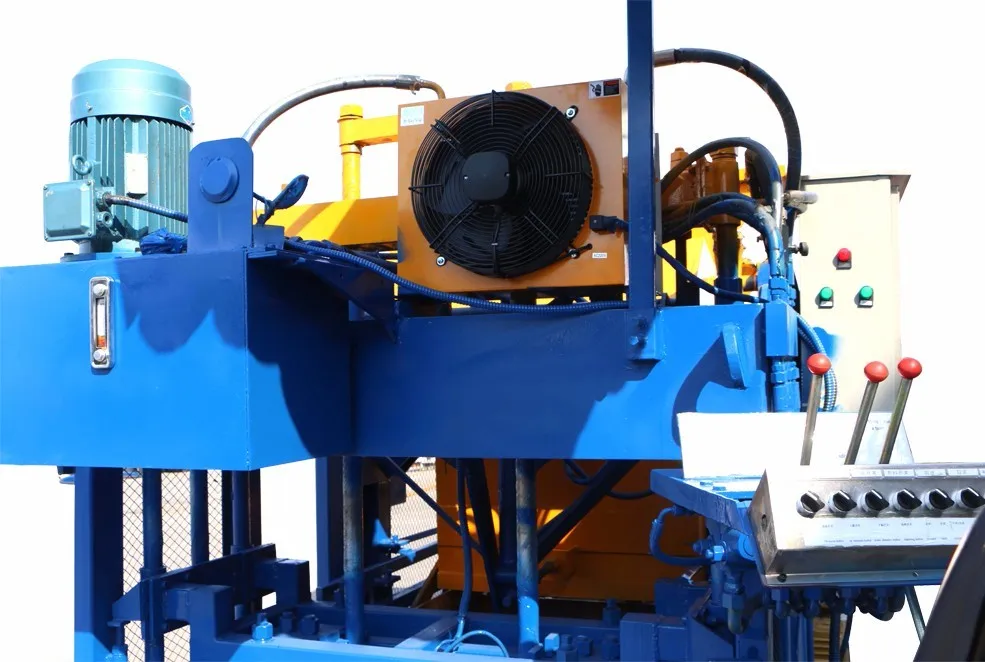

The moulds adopt precise wire cutting technology and carburizing treatment technology to prolong service life, elaborate process and rigorous testing ensure that the mold has the best quality.

4. High capacity

Hydraulic moving cinder fly ash concrete building block making machine can produce 16000-32000 pieces blocks per day according block size.

Afrikaans

Afrikaans Albanian

Albanian Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Chinese(Simplified)

Chinese(Simplified) Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Galician

Galician Georgian

Georgian German

German Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Korean

Korean Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Portuguese

Portuguese Romanian

Romanian Russian

Russian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh