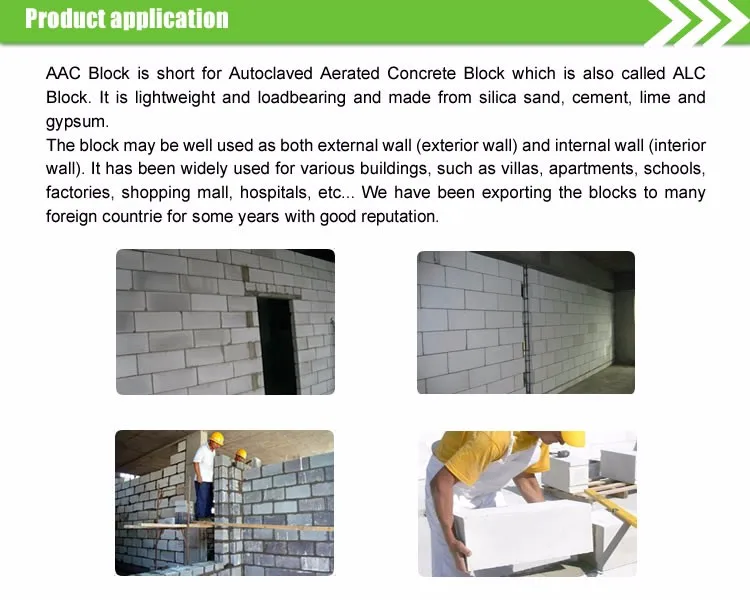

AAC Block Introduction

AAC (Autoclaved aerated concrete) block Main raw materials of AAC are siliceous material (sand, fly ash and Silicon tailings) and Calcium materials (lime and cement) mixed with foaming agent (aluminum powder). It is the product of light porous silicate through the following processes: batching, mixing, pouring, hardening, cutting, autoclaving and curing etc. Because of large amount of well-distributed tiny pores after foaming, it is named autoclaved aerated concrete.

AAC Classification : In general, it can be classified according to the types of raw materials, manufacture process and functions. Based on the shape of AAC products, it can be divided into: AAC blocks and AAC panels. It is a revolutionary material offering an unique combination of high durability and strength, low weight, excellent heat insulation, fire resistant, noise absorption, unprecedented build ability and superior ecological green features. In China, AAC is one of the light wall materials which was popularized and applied at the earliest and the most widely.

Working process

AAC Block manufacturering unit

Material dealing process

Put the fly ash or sand into the ball mill to mill via the conveyor belt, after milling, put the slurry into the slurry storage tank by slurry pump.

Batching, mixing and pouring process

The lime, cement will convey by conveyor to the dry powder measure scale to scale separately. The slurry convey by slurry pump then to the automatic scale;the power and slurry put into the mixer,pouring into the mould.

Curing process

After slurry pouring into the mould, put the mould box into the curing room with 50~70℃. After 2-3 hours curing,the blocks become solid

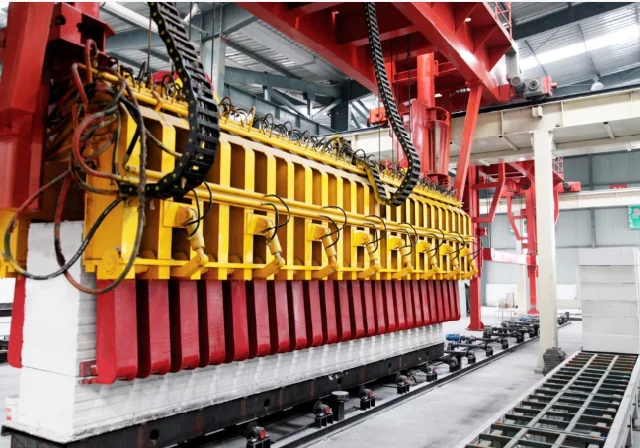

Cutting process

Using reversal crane carry the mould and block to demould on cutting cart. The cutting cart will take the block to level cutting machine,vertical cutting ,two sides cutting,and remove the top waste material.

Autoclaved

Finished cutting using semi-product crane carry to the front of autoclave grouped,hoisting machine or dragger will drag steam trolley into autoclave to steam,it need 10-12 hours.

Finished block dealing

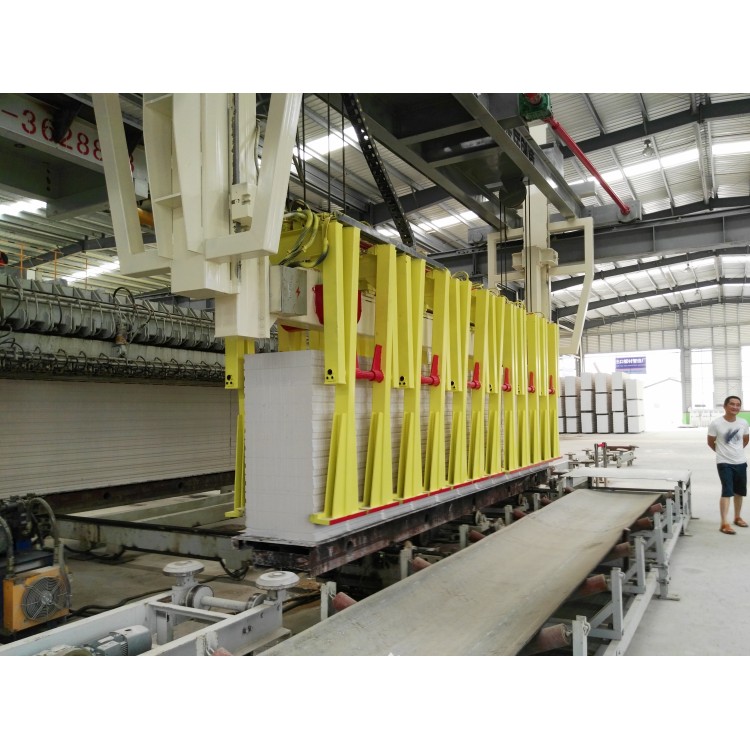

Finished product out of autoclave,with separting machine to separate layer by layer.

Package

Using finished block carry hanger clamp the finished product to package line on wooden pallets,after package, then by forklift transport the finished products to piled yard according to specifications to stack.

Type | TU groove brick | Flat brick without groove |

Length(mm) | 600 | 600 |

Thickness(mm) | 75,100,125,150,200,250,300 | 75,100,125,150,200,250,300 |

Height(mm) | 240,300,400 | 240,300,400 |

AAC Block compression strength of cuber meter

Volume density level | B06 | B05 | B04 |

desiccated density(kg/m³) | ≤625 | ≤525 | ≤425 |

Strength level | A5.0 | A3.5 | A2.0 |

Drying shrinkage date | 0.5 | 0.4 | 0.4 |

Freezing resistance | quality loss % | ≤5.0 | ≤4.0 | ≤3.0 |

Strength after freezing(Mpa) | ≥4.0 | ≥2.8 | ≥0.6 |

Dry coefficient of thermal conductivity

[W/(m•k)] | ≤0.16 | ≤0.14 | ≤0.12 |

Chinese supplier Dongyue automatic aac plant low investment with high profit material description

Fly-Ash:A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the entrepreneur.

Sand (65-70%): the core raw material of AAC product; the main resource of silica-aluminum components; correspond with JC409-91; the clay should less than 4%

Lime(12-20%):one of the main raw materials of fly ash AAC; the main effect is to provide efficient calcium oxide with cooperation of cement making calcium oxide react with SiO2,Al2O3 in hot water then to produce calcium silicate hydrate. Therefore, lime is also the main resource of strength. Effective calcium oxide of lime should not less than 65%, over 80% is perfect and should accord with JC/T621-1996.

Cement(8-10%): This Project aims to utilize OPC cement as main binder material. It will give faster strength to the bricks, besides giving improved consistent quality. It also ensures a better cost effectiveness for the same. Using OPC will be a standardized practice. The other prime advantages of using OPC (compared to other binders) is it's easy availability locally through nationwide Retail Network of Cement Companies.

Gypsum(1-2%):Gypsum is the foaming regulator in AAC which dispels quicklime and postpones slurry's densification.CaSO4 should be more than 70%.

Aluminum Podwer(0.074%):it is the forming agent type and recommendation for supply depend on raw materials and mix formula

Afrikaans

Afrikaans Albanian

Albanian Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Chinese(Simplified)

Chinese(Simplified) Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Galician

Galician Georgian

Georgian German

German Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Korean

Korean Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Portuguese

Portuguese Romanian

Romanian Russian

Russian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh